Hydraulic Compost Turning Machine

Fermentation Compost Turning

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

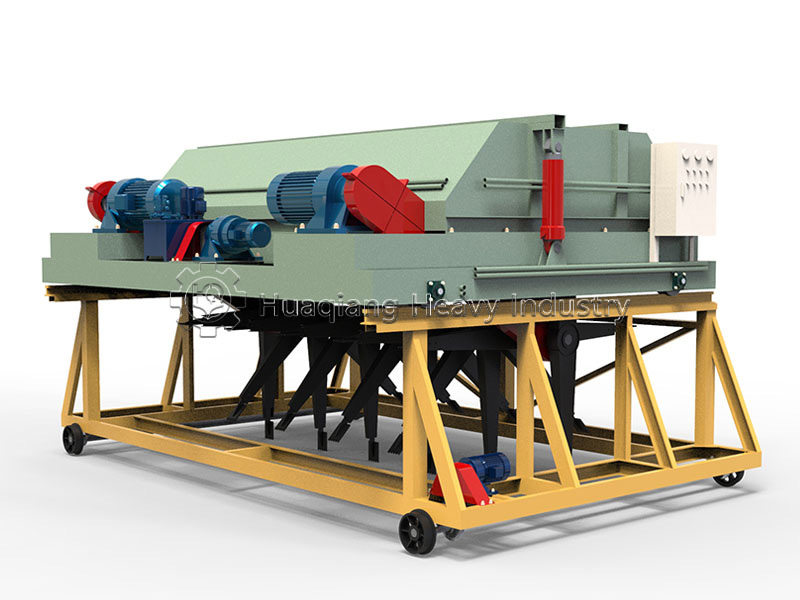

Hydraulic Compost Turning Machine

Hydraulic trough type turning machine is a turning equipment driven by a hydraulic system, specifically used for aerobic fermentation treatment of organic materials such as livestock manure, crop straw, kitchen waste, etc. It promotes the decomposition and transformation of organic materials, accelerates the fermentation process, and is widely used in fields such as organic fertilizer production, bioenergy, and environmental protection treatment through operations such as flipping, stirring, and oxygen supply.

Equipment Structure And Composition

The hydraulic trough type stacker mainly consists of the following parts:

Walking mechanism: including hydraulic motor, walking wheel, guide rail, etc., used to drive the flipping machine to move smoothly along the fermentation tank.

Stacking and mixing mechanism: using a hydraulic driven mixing blade or screw, it penetrates deep into the material pile to achieve flipping and mixing, increase oxygen supply, and promote fermentation.

Hydraulic system: including hydraulic pump, oil cylinder, control valve, etc., providing power for the walking mechanism and the flipping and mixing mechanism, achieving precise control.

Oxygen supply system: Oxygen is supplied to the fermentation tank through a fan or pipeline system to ensure the oxygen required for microbial activity and promote fermentation efficiency.

Control system: including PLC or microcomputer control system, realizing automated operations such as walking, flipping, stirring, and oxygen supply control.

Safety protection system: including overload protection, emergency stop and other safety devices to ensure the safety of equipment and operators.

Working Principle

The working principle of the hydraulic trough type flipping machine is: organic materials are stacked in the fermentation tank, and the flipping machine moves along the tank through a walking mechanism. At the same time, the flipping and stirring mechanism penetrates deep into the material pile, using the power provided by the hydraulic system to flip and stir, fully mixing the upper and lower layers of materials, increasing oxygen supply, promoting microbial activity, and accelerating the decomposition and transformation of organic materials. The oxygen supply system supplies oxygen to the fermentation tank according to the fermentation requirements, ensuring the smooth progress of the fermentation process. Through regular flipping and oxygen supply, organic materials undergo aerobic fermentation under suitable conditions, ultimately producing mature organic fertilizers or bioenergy raw materials.

Equipment Features

Strong power: The hydraulic system provides powerful power, with good flipping and mixing effects, and can handle high-density and viscous materials.

Precise control: The hydraulic drive and control system achieve precise operation, with adjustable flipping depth, speed, and oxygen supply, improving fermentation efficiency and quality.

Smooth operation: The hydraulic system ensures smooth operation of the equipment, reduces mechanical impact, and extends equipment lifespan.

High degree of automation: achieving automated flipping and oxygen supply, reducing manual operations, improving production efficiency, and reducing labor intensity.

Strong adaptability: Suitable for fermentation treatment of various organic materials, including organic waste from different sources and characteristics.

Environmental protection and energy conservation: promote the resource utilization of organic waste, reduce environmental pollution, and have relatively low energy consumption for equipment operation.