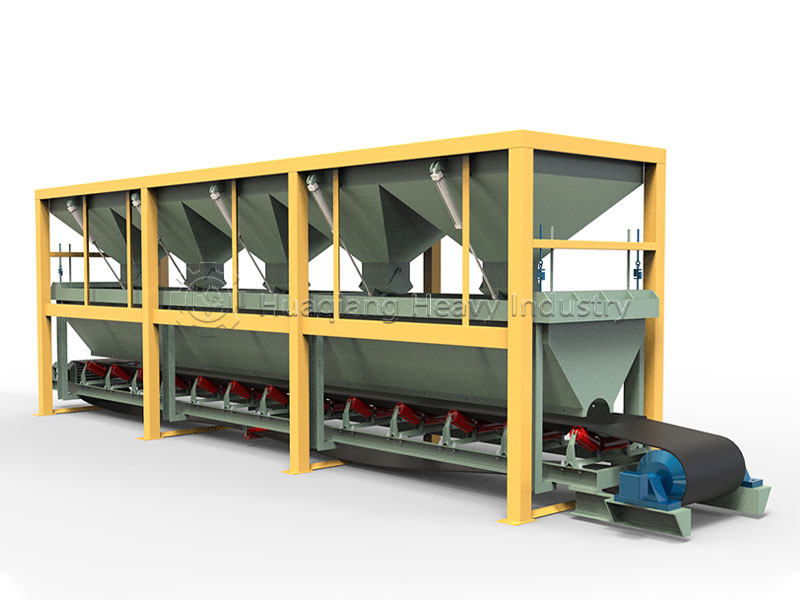

Multiple Silos Single Weigh Type

Automatic Batching System

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Multiple Silos Single Weigh Type

The multi warehouse weighing automatic batching system is a highly integrated automated material processing equipment widely used in industries such as chemical, pharmaceutical, food, and plastic processing. This system is capable of processing multiple different materials simultaneously, accurately measuring them through an independent weighing system to ensure that they are mixed according to preset proportions, in order to meet the strict requirements for material ratios in the production process.

Equipment Structure And Composition

The multi warehouse weighing automatic batching system mainly consists of the following parts:

Multiple material warehouses: used to store different types of raw materials, each warehouse is independent to prevent cross contamination of materials.

Independent weighing unit: Each material warehouse is equipped with a high-precision electronic scale below, which is used to accurately measure the weight of each material.

Material conveying system: including screw conveyor, pneumatic conveying system, vibrating conveyor, etc., used to transport materials from various warehouses to weighing units or mixers.

Central mixer: used to receive and mix all accurately measured materials to generate a uniform mixture.

Control system: including PLC or industrial computer control system, used to coordinate material conveying, weighing, mixing and other operations to achieve automated batching.

Safety and monitoring system: including overload protection, emergency stop button, material detection sensor, etc., to ensure safe operation of equipment and correct handling of materials.

Working Principle

The workflow of the multi warehouse weighing automatic batching system is as follows: Firstly, set the ratio and total amount of each material according to the production formula. After the system is started, materials are transported from their respective independent warehouses to the corresponding weighing units through the conveying system. The electronic scale accurately measures the weight of each material, and when the preset value is reached, the system automatically stops material transportation. Then, all weighed materials are sent to the central mixer for mixing to ensure uniform distribution of the materials. After mixing is completed, the finished product is transported to the next production stage, such as packaging, molding, etc.

Equipment Features

High precision ingredients: Independent weighing units ensure that each material is added in precise proportions, improving the consistency and stability of product quality.

Highly automated: Automated control of material conveying, weighing, and mixing processes, reducing manual operations and improving production efficiency.

Flexibility and adaptability: able to handle various types and characteristics of materials, including solid, liquid, viscous materials, etc., suitable for various production formulas.

Efficiency: Multiple material warehouses and weighing units work in parallel, reducing batching time and increasing production line throughput.

Easy to clean and maintain: The independent material warehouse and conveyor system are easy to clean, reduce cross contamination, and easy to maintain.

Safety and Environmental Protection: The safety protection system and enclosed design reduce operational risks and environmental pollution, meeting industrial safety and environmental standards.