Screw Conveyor

Fertilizer Conveyor

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

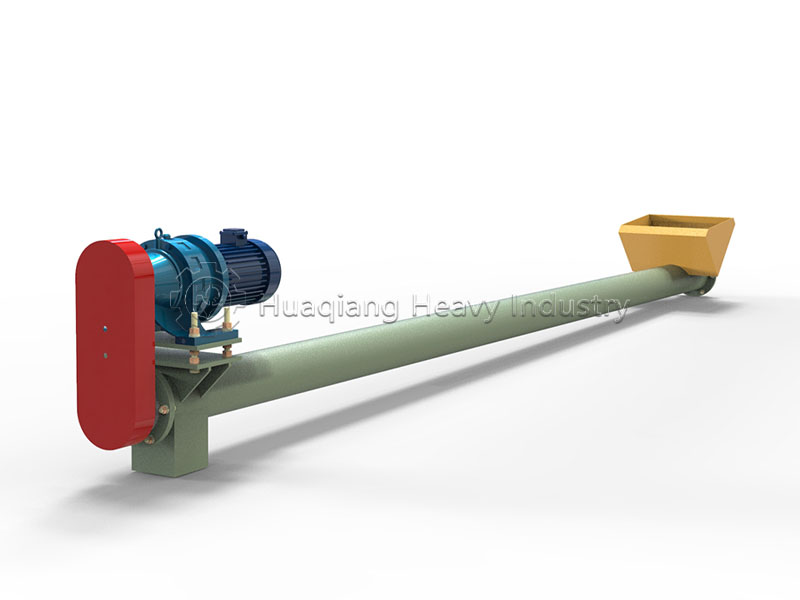

Screw Conveyor

Spiral conveyor, also known as spiral feeder or spiral elevator, is a conveying equipment that uses spiral blades to rotate inside a fixed cylinder and push materials forward. It is suitable for horizontal, inclined, and even vertical transportation of various powdery, granular, and small block materials, and is widely used in industries such as chemical, building materials, food, environmental protection, and coal.

Equipment Structure And Composition

The main structure and components of a screw conveyor include:

Spiral shaft: The spiral shaft is welded with spiral blades and is the core component of material conveying.

Conveyor tube: usually cylindrical, used to accommodate spiral shafts and materials, ensuring that materials are transported in a closed environment and reducing dust flying.

Drive device: including motor and reducer, providing rotational power for the screw shaft.

Inlet and outlet: The inlet is used for adding materials, and the outlet is used for discharging materials.

Support frame: used to support the conveyor drum and ensure the stability of the equipment.

Sealing device: installed at the inlet and outlet to prevent material leakage and external impurities from entering.

Control device: used to control the start stop and adjust the conveying speed of the conveyor.

Working Principle

The working principle of a screw conveyor is based on the rotational motion of the spiral blades:

Material feeding: The material enters the conveyor through the feeding port.

Spiral conveying: The driving device is activated to drive the spiral shaft to rotate, and the spiral blades push the material forward.

Material discharge: When the material reaches the discharge port, it is discharged from the conveyor due to gravity or the pushing effect of the spiral blades.

Equipment Features

Good sealing: The enclosed design of the conveyor drum effectively prevents material leakage and dust pollution, making it suitable for places with high environmental requirements.

Simple structure: composed of basic components such as a spiral shaft, a conveyor tube, and a driving device, the structure is compact and easy to maintain.

Wide applicability: It can transport various powdered, granular, and small block materials, and can achieve conveying at different angles, including horizontal, inclined, and vertical.

Easy to operate: The conveying speed can be adjusted through the control device to achieve quantitative conveying of materials.

Relatively low energy consumption: Compared to other types of conveying equipment, screw conveyors have lower operating energy consumption and better economy.

Low maintenance cost: The structure is simple, the main components are easy to replace, and the maintenance cost for long-term operation is relatively low.