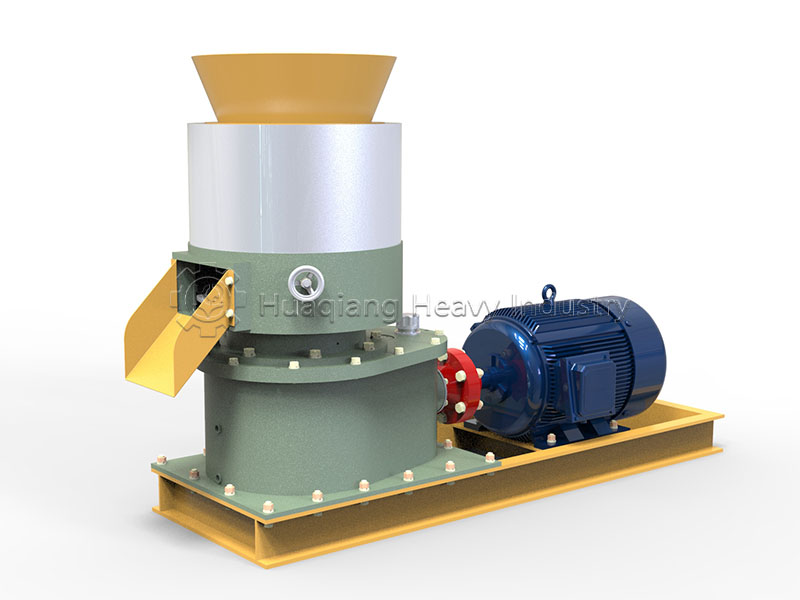

Flat Die Pelleting Machine

Fertilizer Granulator Machine

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Flat Die Pelleting Machine

The flat die granulator is a device that granulates materials through mechanical extrusion. It uses a room-temperature granulation process and is widely used in the field of pellet forming. Its core working principle is to convey pre-treated material between a flat die and a pressure wheel. The pressure wheel, driven by power, applies pressure to the material, forcing it through the die holes in the flat die to form columnar pellets. The pellets are then cut into pellets of a set length.

This granulation method eliminates the need for high-temperature drying, maximizing the retention of active ingredients in the material and making it particularly suitable for granulating heat-sensitive materials. Compared to traditional granulation equipment, it offers a simpler and more compact structure, easier operation, and lower energy consumption. The production capacity of a single unit can be adjusted based on demand, ranging from tens of kilograms to several tons per hour, meeting the needs of production at various scales.

Scope Of Application

Fertilizer field: It can produce a variety of fertilizers, including organic fertilizer, bio-organic fertilizer, compound microbial fertilizer, etc. It can ferment organic waste such as livestock and poultry manure, straw, and mushroom residue into granular fertilizer, solving the problem of traditional organic fertilizers being easy to clump and difficult to transport.It can also be used to produce special fertilizers such as slow-release fertilizers and controlled-release fertilizers. By adjusting the raw material ratio and granulation parameters, the nutrients in the fertilizer can be slowly released to meet the needs of crops at different growth stages.

Feed industry: Suitable for producing various types of pellet feed for livestock, poultry, aquatic products, etc., by mixing corn, soybean meal, fish meal and other raw materials according to the formula and then pelletizing them to improve the palatability and digestibility of the feed and reduce feed waste.

Biomass energy industry: Biomass raw materials such as wood chips, straw, and rice husks can be made into pellet fuel, which has the characteristics of high combustion efficiency and low pollution. It can replace coal in heating, power generation and other fields.

Chemical industry: It can granulate chemical raw materials such as plastics, rubber, pigments, etc., which is convenient for subsequent processing and use, and improves the stability and fluidity of the products.

Pharmaceutical industry: Used for the molding of some medicinal granules. It can maintain the stability of drug ingredients during the granulation process and ensure the quality of drugs.

Equipment Structure And Composition

Feeding device: It usually consists of a hopper and a screw feeder. The hopper capacity is designed according to the production scale, generally 0.5-3 cubic meters, and is used to temporarily store materials to be granulated.The spiral feeder, controlled by a variable frequency motor, delivers the material evenly and continuously between the flat die and the pressing wheel, ensuring a stable feed rate and uniform granulation. Some equipment also features a stirring device to prevent material agglomeration in the hopper.

Flat mold: As the core working component, it is forged from high-strength alloy steel. After heat treatment, the surface hardness can reach HRC55-60, and it has good wear resistance and pressure resistance.The flat die surface is evenly distributed with several die holes. The die hole diameter is usually 2-12 mm, and can be selected according to the desired particle size. The arrangement and distribution density of the die holes are optimized to ensure uniform force on the material and improve granulation efficiency.

Pressure wheel: There are usually 2-4 rollers, symmetrically distributed above the flat die, made of wear-resistant cast iron or alloy steel. The surface of the roller is usually provided with anti-skid patterns to increase friction with the material and prevent the material from slipping.The gap between the pressing wheel and the flat die can be adjusted by the adjusting device to ensure that appropriate pressure is applied to the material. The pressure can be controlled within a certain range according to the material characteristics.

Cutting device: It consists of a blade and a drive mechanism and is installed under the flat die. The blade is made of high-speed steel or alloy tool steel, which is sharp and durable.By adjusting the blade speed and the distance from the flat die, the particle length can be precisely controlled to meet the specification requirements of different products.

Drivetrain: It consists of a motor, a speed reducer, and a chain or gear transmission mechanism. The motor power depends on the equipment model and is generally 3-30kW. The speed reducer transmits power to the pressing wheel and cutting device to ensure the coordinated operation of all components.Some equipment adopts a stepless speed change system, which can flexibly adjust the speed of the pressing wheel to meet the granulation needs of different materials.

Working Principle

Raw material pretreatment: The organic fertilizer raw materials (such as livestock and poultry manure, straw, etc.) are fermented and composted. The fermented materials need to be crushed to a particle size of 80-100 mesh to ensure the granulation effect.For compound fertilizers, basic fertilizers such as nitrogen, phosphorus, and potassium need to be measured according to the formula ratio and then mixed. The mixing uniformity should reach more than 90%, and the moisture content of the mixed material should be controlled between 15% and 25%.

Feeding and extrusion granulation: The pretreated material enters between the flat die and the pressing wheel through the feeding device. The pressing wheel rotates under power drive, exerting pressure on the material, so that the material overcomes the resistance of the die hole and is squeezed into columnar particles and squeezed out of the die hole.During the extrusion process, the pressure and speed of the pressing wheel need to be adjusted according to the material characteristics. Generally, the pressure is controlled at 10-30MPa and the speed is 10-30 rpm to ensure good particle formation.

Cutting and screening: The cylindrical particles extruded from the die hole are cut into particles of a set length by a cutting device, and the length is usually 2-8 mm.The cut particles enter the screening equipment and are screened through sieves of different mesh sizes to separate unqualified particles (too large or too small). The unqualified particles are returned for re-granulation, and the qualified particles enter the next stage.

Cooling and packaging: Granular fertilizers with a high moisture content need to be cooled, usually by air cooling, to reduce the temperature of the granules to room temperature to prevent the granules from clumping.The cooled particles are packaged after being measured. The packaging materials can be woven bags, plastic bags, etc., which are convenient for storage and transportation.

Equipment Features

Simple structure and easy operation: The equipment has few parts, a compact structure, a small footprint, and is easy to install and debug. Operators can start operation after simple training, and the daily maintenance workload is small, making it suitable for small and medium-sized fertilizer production enterprises.

Strong adaptability of raw materials: It can process a variety of fertilizer raw materials, whether it is organic fertilizer raw materials with high fiber content or compound fertilizer raw materials with high viscosity, and can achieve effective granulation. It also has a certain tolerance for raw materials containing small amounts of impurities.

Good particle quality: The fertilizer particles produced have high density and strength, generally reaching 15-40N, are not easy to break, and have good stability during storage and transportation. The particles have regular shape and smooth surface, which is convenient for fertilization operation.

Low energy consumption and low cost: Without the need for a drying step, energy consumption is only 40%-60% of that of wet granulation equipment, significantly reducing production energy costs. The equipment purchase cost is relatively low, and the investment payback period is short, making it suitable for initial investment by companies with limited funds.

Flexible and adjustable, wide applicability: By replacing flat dies of different specifications, pellets of different diameters can be produced to meet the needs of different crops and fertilization methods. The pressure and speed of the pressing wheel can be flexibly adjusted to adapt to the granulation characteristics of different raw materials.