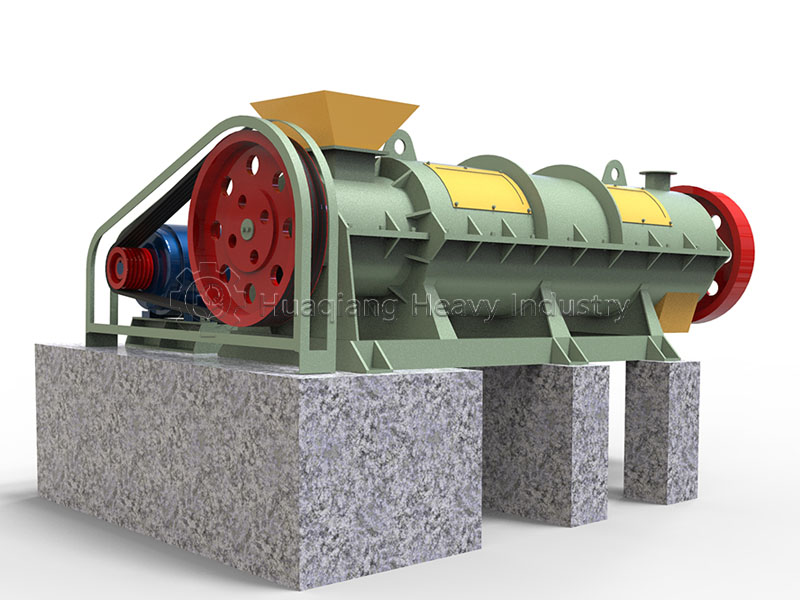

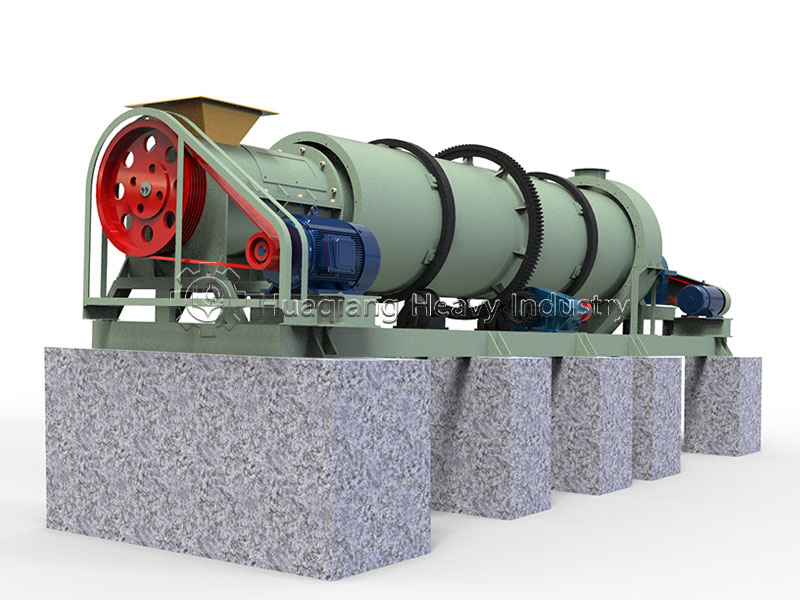

New Type Two In One Organic Fertilizer Granulator

Fertilizer Granulator Machine

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

New Type Two In One Organic Fertilizer Granulator

The new two-in-one organic fertilizer granulator is a highly efficient granulation device that combines mixing and granulation functions. Designed specifically for organic fertilizer production, it achieves integrated material mixing and granulation. Its core operating principle is that after fermented organic raw materials are fed into the machine, they are first thoroughly mixed by a built-in stirring device to achieve uniform distribution of the material components. The machine then switches to granulation mode, where a special granulation mechanism (typically combining stirring, extrusion, or rolling principles) processes the mixed material, causing it to agglomerate into granules through mechanical force and its own viscosity.

This two-in-one design eliminates the material transfer process between the mixing and granulation equipment in traditional production, reducing material loss and energy consumption, and significantly improving production efficiency. Compared with single-function granulation equipment, it occupies a smaller area and is more convenient to operate, making it particularly suitable for small and medium-sized organic fertilizer manufacturers to achieve intensive production.

Scope Of Application

Organic fertilizer production field: It can process various organic waste raw materials, such as livestock and poultry manure (chicken manure, pig manure, cow manure, etc.), crop straw, edible fungus residue, wine lees, vinegar lees, municipal sludge, etc., and convert them into commercial organic fertilizer granules.

It is suitable for the production of organic fertilizer for self-use in large-scale organic fertilizer production plants, organic fertilizer processing cooperatives and large-scale planting bases. It can meet the granulation needs of organic fertilizers of different scales. The granular organic fertilizers produced can be used in farmland, orchards, vegetable gardens, flower planting and other scenarios.

Other related fields: In the production of organic-inorganic compound fertilizers, it can be used for the pretreatment and granulation of the organic part, and then mixed with inorganic fertilizers to produce compound fertilizers with the advantages of both organic and inorganic fertilizers.

It can also be used in the production of bio-organic fertilizer. During the granulation process, it can better retain the activity of beneficial microorganisms and ensure the functionality of the bio-organic fertilizer.

Equipment Structure And Composition

Hybrid system: It consists of a mixing shaft, mixing blades, and a mixing chamber. The shaft is made of high-strength alloy steel, with bearings installed at both ends to ensure stability. The mixing blades are distributed in a spiral or paddle shape and are made of wear-resistant cast iron or stainless steel, which can be selected according to the characteristics of the material.

The mixing silo’s capacity is designed based on production scale, typically ranging from 1 to 8 cubic meters. Its inner walls feature rounded transitions to minimize material residue. The mixing system is driven by a variable-frequency motor with an adjustable speed between 20 and 60 rpm, ensuring a mixing uniformity of at least 90%.

Granulation system: The core components include a pelletizing disc (or drum), a forming mechanism, and a transmission. The disc’s tilt angle is hydraulically adjustable (ranging from 30° to 50°). The disc is constructed of stainless steel and lined with a wear-resistant rubber lining to reduce material wear and adhesion.

The forming mechanism is categorized as agitator, roller, or combination types, depending on the granulation principle. The agitator uses high-speed rotating teeth to aggregate the material into granules, while the roller-type forms the material through the compression of rollers and a mold plate. The transmission uses a reduction motor with a power of 11-45kW, depending on the machine model, to ensure a stable granulation process.

Feeding and discharging devices: The feeding device consists of a hopper and a screw feeder. The hopper is equipped with a liquid level sensor to automatically control the feeding amount. The screw feeder adopts variable frequency speed regulation to match the conveying amount with the mixing and granulation rhythm.

The discharging device is located at the end of the granulation system. It is an inclined chute or belt conveyor. A vibration device is installed at the bottom of the chute to prevent material blockage and transport the formed granules to the subsequent process.

Control system: The PLC touchscreen control system integrates monitoring and adjustment functions for parameters such as mixing time, granulation speed, material moisture, and output. Sensors are equipped to monitor material status in real time. When indicators such as moisture and mixing uniformity deviate from set values, automatic alarms and prompts for adjustments are generated, enabling intelligent production.

Working Principle

Raw material pretreatment: Crush fermented and decomposed organic materials (such as livestock and poultry manure and straw) to a particle size of 40-60 mesh, removing impurities such as stones and plastic. Test the moisture content of the raw materials and control the moisture content to 25%-35% by airing or adding water. Excessively high moisture content can easily cause pellets to stick together, while too low a moisture content can make pellets difficult to form.

Mixing stage: The pretreated raw materials enter the mixing system through the feeding device. A small amount of binder (such as bentonite, starch, etc., generally not exceeding 3%) is added as needed. The stirring device is started and the mixing time is set to 5-10 minutes to fully mix the raw materials and additives, ensuring uniform material composition and laying the foundation for subsequent granulation.

Granulation stage: After mixing, the material automatically enters the granulation system. The granulation mode is selected based on the material’s characteristics: if the material is highly viscous, use the agitator granulation method, where the teeth and claws stir the material at high speed to agglomerate it into 1-6 mm particles. If the material has a high fiber content, switch to the roller granulation method, where rollers squeeze the material through a die plate to form it.

During the granulation process, the material humidity is adjusted in real time through the water spray device to maintain the stability of the granule formation. The formed granules are transported to the screening stage through the discharging device.

Screening and return: The finished particles enter the vibrating screen and are screened through a 1-6 mm sieve. Qualified particles enter the drying process; the fine powder and oversized particles screened out are sent back to the mixing system through the return device for re-granulation. The raw material utilization rate can reach more than 95%.

Drying and packaging: Qualified pellets enter the dryer and are dried at 60-80°C to a moisture content below 10% to prevent mold during storage. The dried pellets are cooled, measured, and packaged in woven or laminated bags for easy storage and transportation.

Equipment Features

High degree of integration: The mixing and granulation functions are integrated into one, eliminating the need for conveying equipment between the mixer and granulator in traditional production lines, reducing material losses during transportation (the loss rate is reduced from the traditional 5%-8% to 1%-2%), and saving 30%-50% of the equipment floor space.

High production efficiency: Integrated operations shorten production cycles, enabling a single unit to produce 1-5 tons of product per hour, a 20%-40% increase compared to traditional, split-type equipment. This also reduces equipment startup and shutdown times and material waiting times, making it suitable for continuous production.

Good granulation effect: The granulation mechanism is designed according to the characteristics of organic fertilizer raw materials. It can adapt to high-fiber, high-moisture organic materials. The granules produced have high roundness (sphericity above 85%) and moderate granule strength (10-30N). They are easy to transport and can be naturally decomposed in the soil.

Low energy consumption and cost: The integrated design reduces the number of power equipment such as motors, and reduces energy consumption per unit product by 15%-25% compared to traditional production lines. It also reduces the number of equipment maintenance points and operators, lowering production management costs.

Strong operational flexibility: The control system can flexibly adjust parameters such as mixing time, granulation speed, and humidity to meet the granulation needs of different organic raw materials (such as chicken manure, straw, sludge, etc.). There is no need to adjust the equipment on a large scale when changing raw materials.