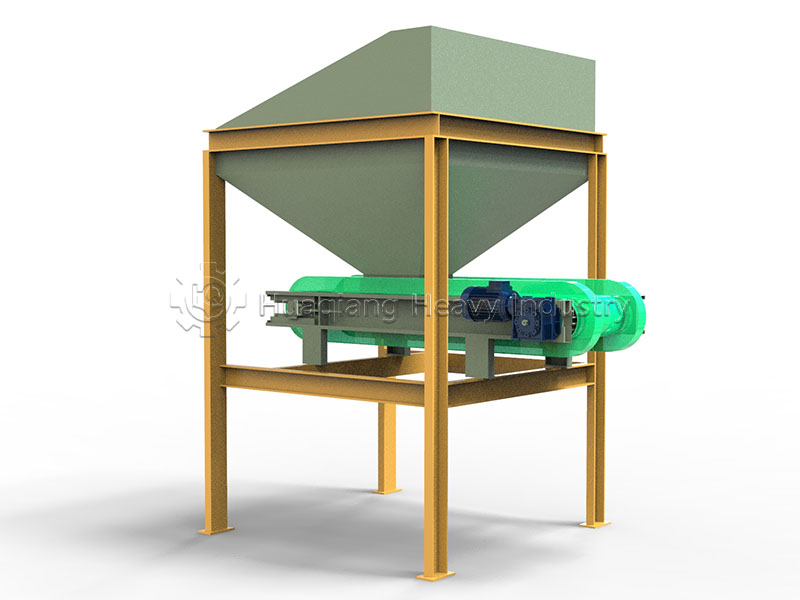

Single Silo Single Weigh Type

Automatic Batching System

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Single Silo Single Weigh Type

The single warehouse weighing automatic batching system is an automated equipment used for precise measurement and mixing of various materials, widely used in industries such as chemical, pharmaceutical, food, and building materials. The system accurately measures each material through independent weighing units, and then mixes them according to preset formula ratios to ensure the stability of product quality and the efficiency of the production process.

Equipment Structure And Composition

The single warehouse weighing automatic batching system mainly consists of the following parts:

Material warehouse: used to store different types of raw materials, each warehouse is independent to avoid cross contamination of materials.

Weighing unit: Each material warehouse is equipped with high-precision electronic scales below, which are used to accurately measure the weight of each material.

Conveyor device: including screw conveyor, belt conveyor or pneumatic conveying system, used to transport materials from the material warehouse to the weighing unit or mixer.

Mixer: Used to mix accurately measured materials according to formula proportions to generate a uniform mixture.

Control system: including PLC or microcomputer control system, used to control material conveying, weighing, mixing and other processes, achieving automatic batching.

Safety protection system: including overload protection, emergency stop and other safety devices to ensure the safety of equipment and operators.

Working Principle

The working principle of the single warehouse weighing automatic batching system is: first, set the ratio and total amount of each material according to production needs. After the system is started, materials are sent from their respective material warehouses to the weighing unit through the conveying device. The electronic scale accurately measures the weight of each material to ensure that it meets the preset formula ratio. When all materials reach the specified weight, the system controls the conveying device to send the materials into the mixer for mixing. After mixing is completed, the system can automatically control unloading and proceed to the next process, such as packaging or further processing.

Equipment Features

High ingredient accuracy: Independent weighing is used to ensure that each material is added according to precise weight, improving the stability of product quality.

High degree of automation: realizing the automation of material conveying, weighing, mixing and other processes, reducing manual operations, and improving production efficiency.

Strong adaptability: able to handle a variety of materials, including powders, particles, liquids, etc., suitable for various formula requirements.

Easy to operate: friendly human-machine interface, simple parameter settings, easy to operate and maintain.

Security: The security protection system ensures the safe operation of equipment and reduces production accidents.

Environmental protection and energy conservation: The enclosed material warehouse and conveying system reduce dust pollution, resulting in lower energy consumption during equipment operation.