When choosing an organic fertilizer production line, how to judge its quality and performance?

Organic fertilizer production line is an indispensable facility in modern agricultural production, which directly affects the yield and quality of organic fertilizer. Selecting the right organic fertilizer production line requires comprehensive evaluation from multiple perspectives.

- Raw material adaptability: We must first consider the adaptability of the production line to raw materials. High-quality Organic Fertilizer Production Linecan adapt to a variety of raw materials, including livestock manure, straw, food industry by-products, etc. The diversity of raw materials directly affects the nutritional value and production cost of organic fertilizers.

- Production capacity: The production capacity of the production line should match the scale and needs of the farm. For example, for large-scale farms, you may need to choose a production line that produces hundreds of tons per day, while for small-scale farms, you may need to choose a production line that produces tens of tons per day.

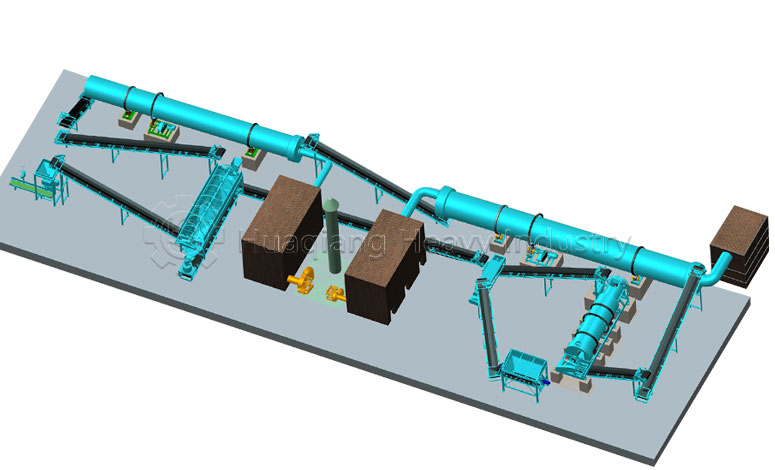

- Equipment composition: Organic fertilizer production line usually includes grinding, mixing, granulation, drying, screening and packaging and other links. The equipment performance of each link will affect the quality of the final product. For example, the Disc Granulator is able to produce uniform particles, which helps to improve fertilization efficiency.

- Environmental performance: In the production process, the production line should meet the environmental requirements and reduce the impact on the environment. This includes emission reduction, noise control, waste disposal and more.

- Degree of automation: modern organic fertilizer production lines are increasingly inclined to automation, which can reduce labor costs and improve production efficiency. Production lines with a high degree of automation can more accurately control various parameters in the production process.

- Energy consumption: The energy consumption of the production line is also an important indicator to measure its performance. Energy efficient production lines can reduce production costs while also meeting the requirements of sustainable development.

- After-sales service: It is important to choose a production line with good after-sales service. This includes services such as installation, commissioning, maintenance and upgrading of equipment.

- Return on investment: Finally, you need to consider the return on investment of the production line. This includes equipment acquisition costs, operating costs and maintenance costs. A high-quality production line should be able to recover the investment cost in a relatively short time.

Through the comprehensive evaluation of the above aspects, the quality and performance of the organic fertilizer production line can be judged, so as to make a reasonable choice.