What are the specific aspects of the maintenance cost of organic fertilizer granulator, and how to effectively reduce the maintenance cost?

The maintenance cost of organic fertilizer granulator mainly includes the following aspects:

- Replacement of wearing parts: In the Organic Fertilizer Production Line, key components such as bearings, gears, rolls, etc. of equipment such as Flat-Die Pellet Machine and Rotary Drum Granulator need to be replaced regularly due to wear and tear.

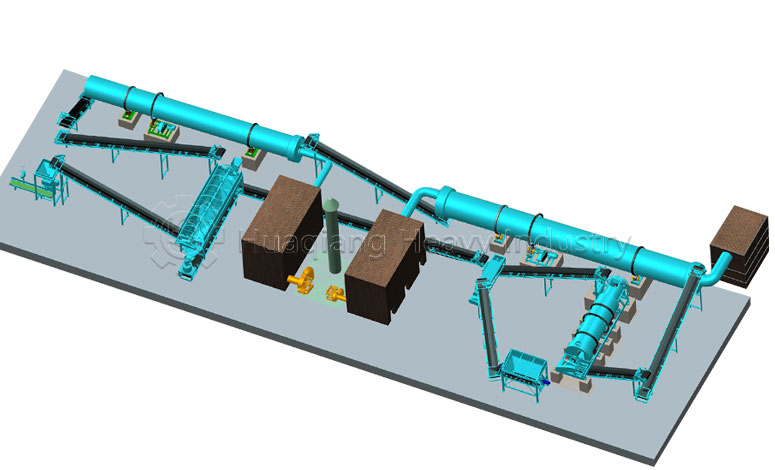

Organic Fertilizer Production Line: It relates to the whole organic fertilizer production process, including all aspects of the granulator. When discussing maintenance costs, we consider the maintenance of the pelletizer part of the line, which is key to ensuring the efficient operation of the entire line.

Flat-Die Pellet Machine: As a choice of organic fertilizer granulation, Flat-Die Pellet Machine has the advantages of strong adaptability to raw materials and does not require raw materials to dry. In the discussion of maintenance costs, we emphasized the importance of regular replacement of wearing parts and lubrication system maintenance, which are key points in the maintenance of Flat-Die Pellet machines.

Rotary Drum Granulator: Rotary Drum Granulator is one of the common granulation devices used in the Organic Fertilizer Production Line. Maintenance of Rotary Drum granulator should also be taken into account when discussing maintenance costs, as it may involve similar maintenance work such as part replacement, lubrication, and cleaning.

- Lubrication system maintenance: Good lubrication is essential to the life of moving parts such as bearings, and the quality and replacement of lubricating oil need to be checked regularly to ensure the normal operation of the equipment.

- Equipment cleaning: Regularly clean the residue and dirt inside the pelletizer to prevent clogging and equipment rust, which is also part of the maintenance cost.

To effectively reduce maintenance costs, you can take the following measures:

- Regular maintenance: Perform regular maintenance and inspection as recommended by the device manufacturer to discover and solve problems in a timely manner to prevent minor problems from turning into major faults.

- Use high-quality parts: The use of high-quality wearing parts can extend the replacement cycle and reduce the number of maintenance.

- Operation training: Conduct appropriate training for operators to ensure that they understand the correct operation methods of equipment and the importance of daily maintenance.

Through the above measures, the maintenance cost of the organic fertilizer granulator can be effectively reduced, and the use efficiency and life of the equipment can be improved.