Fertilizer granulator selection Guide: How to choose the right model according to crop needs

In modern agricultural production, fertilizer granulator is the key equipment to improve the utilization rate of fertilizer and meet the specific needs of crops. Choosing the right fertilizer granulator can not only improve the quality of fertilizer products, but also promote the healthy growth of crops. Here is a guide to choosing the right fertilizer granulation machine for your crop needs.

1. Crop demand analysis

First, it is necessary to analyze the characteristics of crop demand for fertilizer nutrients. The proportion and demand of main nutrients such as nitrogen, phosphorus and potassium are different in different crops. For example, leafy vegetables require more nitrogen fertilizer, while fruit trees require more phosphorus and potassium. Therefore, when choosing a fertilizer granulator, it should be considered whether it can meet the nutrient needs of specific crops.

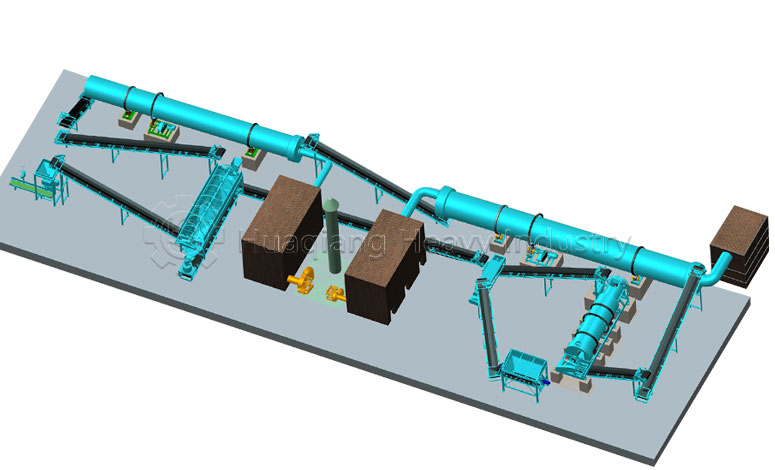

2. Fertilizer Granulating Production Line

The fertilizer pelletizing line includes a variety of equipment, such as shredders, mixers, granulators, dryers and screeners. These devices work together to make the raw material into a granular fertilizer. When selecting, the integrity and synergy of the production line should be considered to ensure that the selected granulator can match the existing equipment to form an efficient production process.

3. Organic Fertilizer Production Line

For the Production of Organic Fertilizer, the Organic Fertilizer Production Line is key. Organic fertilizer is rich in organic matter and can improve soil structure and soil fertility. When selecting organic fertilizer granulator, it is necessary to consider its adaptability to organic raw materials, and whether it can produce uniform and high-quality granular fertilizer while maintaining the activity of organic matter.

4.Fertilizer Granules Compaction Machine

The Fertilizer Granules Compaction Machine is suitable for the production of high density granular fertilizers and is suitable for crops requiring high concentrations of fertilizers. This type of machine can compress fertilizer raw materials into particles through extrusion, improve the density and hardness of fertilizer, and reduce waste during application.

When choosing a fertilizer granulator, the following factors should also be considered:

Production scale: According to the production scale of the farm or fertilizer factory, choose the corresponding capacity of the granulator.

Cost-effectiveness: Considering the acquisition cost, operation cost and maintenance cost of the equipment, choose the cost-effective equipment.

Environmental impact: Choose environmentally friendly, low-energy equipment to reduce the impact on the environment during the production process.

Technical support and after-sales service: Select equipment suppliers with good technical support and after-sales service to ensure long-term stable operation of equipment.

To sum up, choosing the right fertilizer granulator requires comprehensive consideration of crop demand, production line supporting, equipment performance and economic factors. Through scientific and reasonable selection, the utilization efficiency of fertilizer can be improved, the healthy growth of crops can be promoted, and the sustainable development of agriculture can be achieved.