What should be noted when using organic fertilizer fermentation equipment?

Organic fertilizer is an indispensable part of agricultural production, and every link of its production process is crucial. The correct use of organic fertilizer fermentation equipment can not only improve the quality and efficiency of fertilizers, but also ensure the safety and environmental protection of the production process. Here are a few key points to pay attention to when using organic fertilizer fermentation equipment:

- Use of Uniform Feeder: In the production process of organic fertilizer, uniform feeding is an important link to ensure the quality of fermentation. By using a uniform feeder, the material can be ensured to enter the fermentation equipment continuously and evenly, avoiding the problem of incomplete or excessive fermentation caused by uneven feeding.

- Selection and use of fertilizer mixer: mixer plays a role in the production of organic fertilizer. Horizontal Ribbon Mixer and Double Shafts Paddles Mixer are two common types of mixers that ensure an even mix of ingredients and improve fermentation efficiency. When using, pay attention to the mixing speed and time to avoid destroying the microbial activity in organic fertilizer.

- Application of fertilizer Screening Machine: Organic fertilizer will produce materials of different particle sizes during fermentation. The Rotary Screening Machine or Vibration Screening Machine can effectively separate the fertilizer particles that meet the standard and improve the uniformity and quality of the final product.

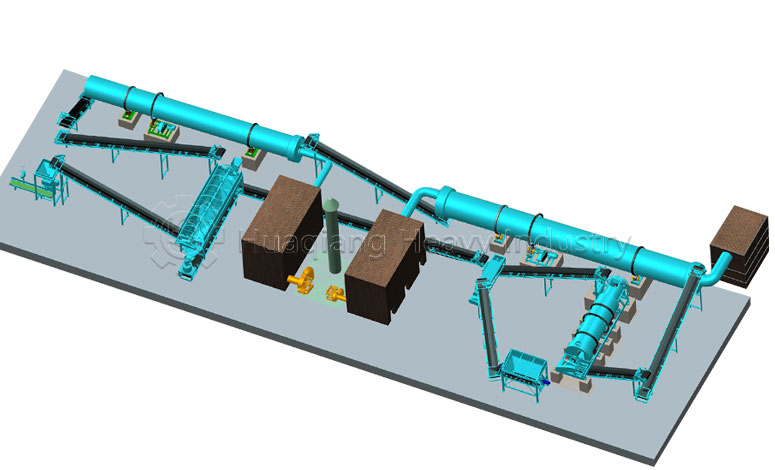

- Maintenance of Organic Fertilizer Production Line: Organic Fertilizer Production Line includes multiple links, such as raw material treatment, fermentation, drying, screening and packaging. Regular maintenance and inspection of all aspects of the equipment, such as Fertilizer Granules Compaction Machine, Flat-Die Pellet Machine, Rotary Drum Granulator, etc., can ensure the continuous and stable operation of the production line. Reduce the risk of failure.

- Operation of Compost Turning Machine: compost turning machine, such as Windrow Compost Turning Machine, is the key equipment to improve the efficiency of compost fermentation. Proper operation can ensure the air permeability and temperature control inside the compost, promote the activity of microorganisms, and accelerate the decomposition of organic matter.

- The rational use of fertilizer crusher: In the production process of organic fertilizer, the crushing of materials is an important step to improve the fermentation efficiency. Equipment such as Cage Crusher can crush large pieces of material into a suitable size for fermentation, but the crushing size should be adjusted to avoid excessive fine materials affecting the fermentation effect.

- Environmental control: During the use of organic fertilizer fermentation equipment, the temperature, humidity and pH value of the fermentation environment need to be strictly controlled to ensure the activity of microorganisms and fermentation efficiency. At the same time, it is also necessary to pay attention to ventilation and stacking to avoid the accumulation of harmful gases.

- Safe operation: When operating organic fertilizer fermentation equipment, the relevant safety procedures must be followed to ensure the safety of the operator. This includes properly wearing protective equipment, following instructions in the operating manual, and conducting regular safety training.

Through the strict implementation of these precautions, you can ensure the efficient, safe and environmentally friendly operation of organic fertilizer fermentation equipment, so as to produce high-quality organic fertilizer to meet the needs of modern agriculture.