How does the Windrow Compost Turning Machine reduce the investment cost of fermentation?

In modern agricultural production, organic fertilizers are gaining more and more attention due to their environmental protection and soil improvement properties. Windrow Compost Turning Machine as a key equipment in Organic Fertilizer Production Line, its high efficiency, energy saving characteristics can effectively reduce the investment cost of fermentation process. This article will explore how to maximize cost effectiveness by using the Windrow Compost Turning Machine, combined with the fertilizer granulator equipment.

1. Improve the utilization rate of raw materials

The Windrow Compost Turning Machine accelerates the decomposition process of microorganisms by evenly turning the compost raw materials to ensure that the raw materials are in full contact with the air. This uniform turning can improve the utilization rate of raw materials and reduce the waste of raw materials. In the Organic Fertilizer Production Line, the efficient use of raw materials is the key to reducing costs. By optimizing the work flow of the pile turning machine, the dependence on nitrogen, phosphate and potassium fertilizers can be reduced, thus reducing production costs.

2. Reduce energy consumption

Compared with the traditional Compost Turning method, the Windrow Compost Turning Machine uses modern mechanical operation, reducing labor costs and time costs. At the same time, the efficient design of the tiller reduces energy consumption, especially in the NPK Fertilizer Production Line, where energy savings directly translate into cost reductions.

3. Improve the quality of granulation

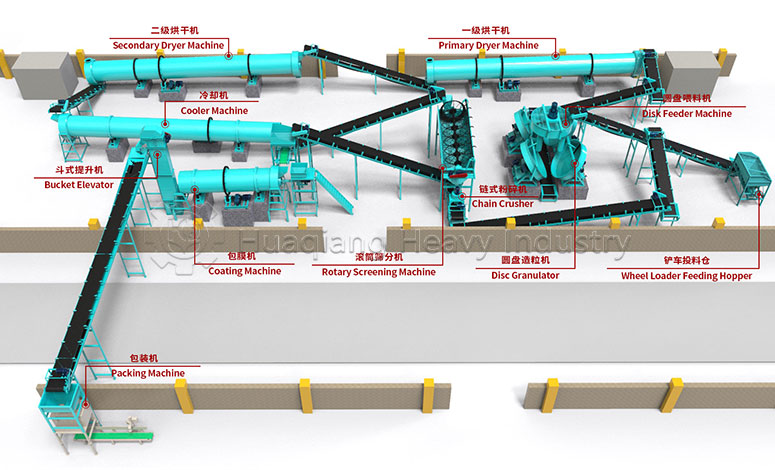

In the Organic Fertilizer Production Line, fertilizer Granulator equipment such as Flat-Die Pellet Machine and Rotary Drum Granulator are indispensable. Windrow Compost Turning Machine provides higher quality raw materials for pelletizer by optimizing the fermentation process. High-quality raw materials can improve the efficiency of the granulator, reduce rework and scrap rates, and thus reduce the overall production cost.

4. Extend the service life of the equipment

A good fermentation process can not only improve the quality of fertilizer, but also extend the service life of fertilizer granulator equipment. Windrow Compost Turning Machine reduces wear on pelletizer equipment by reducing excessive turning of raw materials. For example, the wear rate of Fertilizer Granules Compaction Machineis significantly reduced when handling optimized fermented raw materials, which reduces the cost of maintenance and replacement parts.

Conclusion

The application of Windrow Compost Turning Machine in Organic Fertilizer Production Line effectively reduces the investment cost of fermentation by improving the utilization rate of raw materials, reducing energy consumption, improving the quality of granulation and extending the service life of equipment. In the pursuit of sustainable development today, this efficient and environmentally friendly equipment will undoubtedly become an important choice for organic fertilizer production. Through rational configuration and use of the Windrow Compost Turning Machine, agricultural producers can obtain higher quality organic fertilizers at a lower cost, contributing to the sustainable development of agriculture.