NPK compound fertilizers, widely used in modern agricultural production, undergo a precise and systematic industrial processing procedure. From basic chemical raw materials to uniformly shaped granules, this NPK fertilizer production line integrates chemical synthesis and physical processing technologies, forming a standardized manufacturing system.

Production begins with the precise measurement and synthesis reaction of raw materials. Different proportions of nitrogen, phosphorus, and potassium base materials undergo chemical reactions under controlled conditions to generate a complex containing the target nutrients. This chemical stage establishes the core nutrient content and ratio of the product.

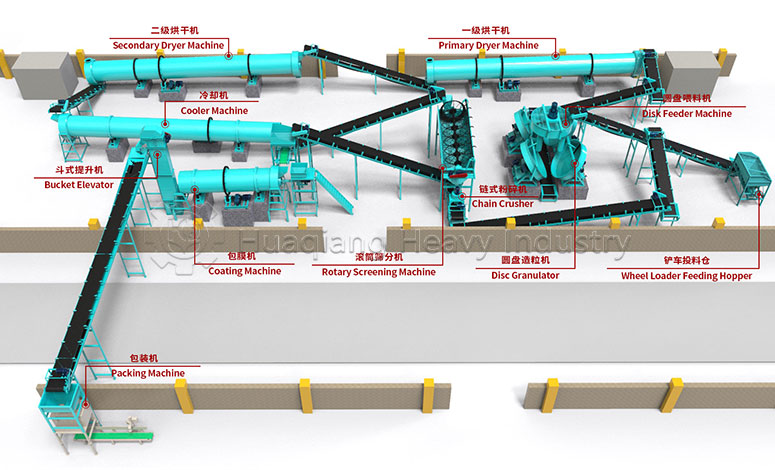

The synthesized slurry then enters the crucial physical molding stage. The rotary drum granulator plays a vital role in this process. By precisely controlling temperature and humidity, these granules achieve a stable physical morphology, preparing them for subsequent processing.

The newly generated granules require complete post-processing. After drying and cooling, the sieving process grades the granules according to their specifications. At this point, lumps with excessively large particle sizes are returned to the previous process, re-crushed in a fertilizer crusher, and then re-granulated. This cycle ensures high raw material utilization and uniform product particle size.

It is worth mentioning that some of the large-particle base fertilizers obtained after drying and screening can be used as raw materials to directly enter another flexible production path—through bulk blending fertilizer machines, they can be quickly and physically mixed with other single-element fertilizers or micronutrients according to actual field needs to produce customized blended fertilizers.