In modern composting and fermentation processes, whether the materials can achieve sufficient and uniform contact with oxygen is crucial in determining the efficiency of decomposition and the final quality. The double screws compost turning machine, with its unique design and working method, is becoming a key technological equipment to solve this core problem, providing a stable and efficient solution for large-scale organic waste treatment.

The core value of this equipment lies in its excellent mixing and homogenization effect. During the turning process, the double helix structure not only breaks up caked materials but also thoroughly exchanges and mixes the surface and bottom layers, as well as the internal and external materials. This three-dimensional mixing method allows moisture, temperature, and microorganisms to quickly become uniform within the compost pile, greatly improving the stability and controllability of the fermentation process.

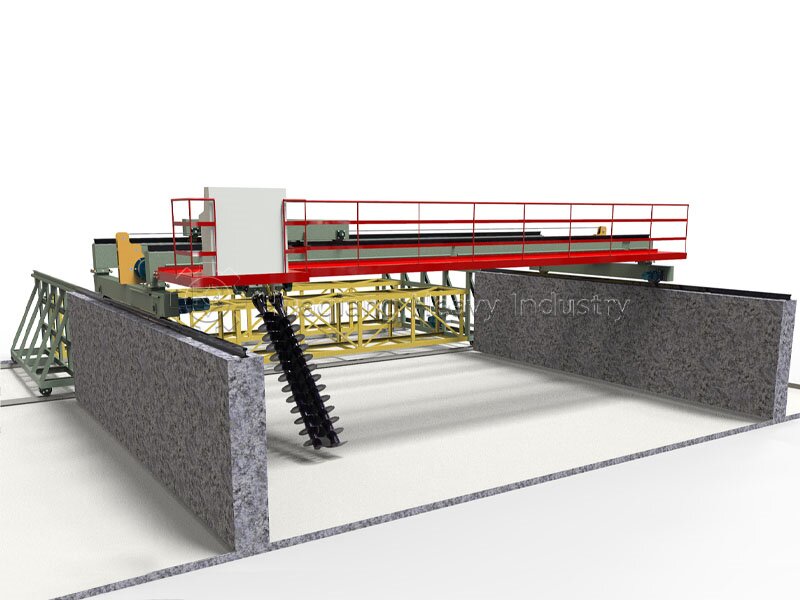

In a complete organic fertilizer production line, the double screws compost turning machine is usually deployed in the core section of windrow composting or trough composting. As the “main force” in the entire organic fertilizer production equipment system, it works closely with the front-end system and the back-end discharge system, achieving continuous operation from raw material entry to the completion of primary fermentation, significantly shortening the fermentation cycle and improving site utilization and production efficiency.

With its reliable and efficient performance, the double screws compost turning machine provides a solid process guarantee for the resource utilization of organic waste and the stable production of high-quality organic fertilizer.