The residue from biogas projects is rich in organic matter and nutrients such as nitrogen, phosphorus, and potassium, making it a high-quality raw material for organic fertilizer. However, direct use can lead to nutrient loss and soil compaction. By scientifically processing it into fertilizer granules, resource utilization can be improved, and the product value can be significantly increased.

The first step is pretreatment and purification. Biogas residue needs to be screened to remove stones, plastics, and other impurities, and then dehydrated to adjust the moisture content to 40%-50%. If the organic matter content of the residue is low, auxiliary materials such as straw powder and composted livestock manure can be added to balance the carbon-nitrogen ratio to 25:1-30:1, laying a foundation for high-quality raw materials for subsequent processing.

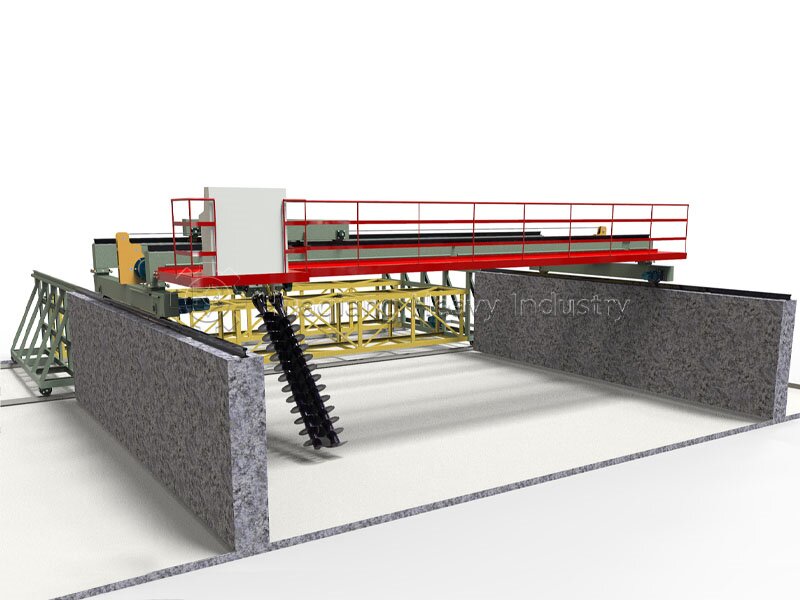

The second step is secondary fermentation optimization. The prepared raw materials are sent to a fermentation tank, where a compost turning machine is used for regular turning and oxygen supply to maintain a high-temperature fermentation environment of 55-65℃ for 7-10 days to kill insect eggs and pathogens, and further decompose difficult-to-degrade components. The fully composted residue has a loose texture and more stable nutrients, preventing secondary fermentation after granulation.

The third step is precise granulation and molding. The composted residue is sent to a granulator. Rotary drum granulators or fertilizer compaction machines are recommended, and the particle size is adjusted according to market demand. A suitable amount of binder can be added during granulation to improve the molding rate. An intelligent temperature control system should also be used to ensure moderate hardness, roundness, and uniformity of the granules, improving the product’s appearance and storage and transportation stability.

Finally, post-processing for quality improvement. After drying and cooling, the formed granules are screened again to remove unqualified particles, resulting in high-value fertilizer products.