The hydraulic compost turning machine is a hydraulic system-driven composting equipment designed for aerobic fermentation of organic materials such as livestock and poultry manure, crop straw, and kitchen waste. It is a core piece of equipment in organic fertilizer production lines.

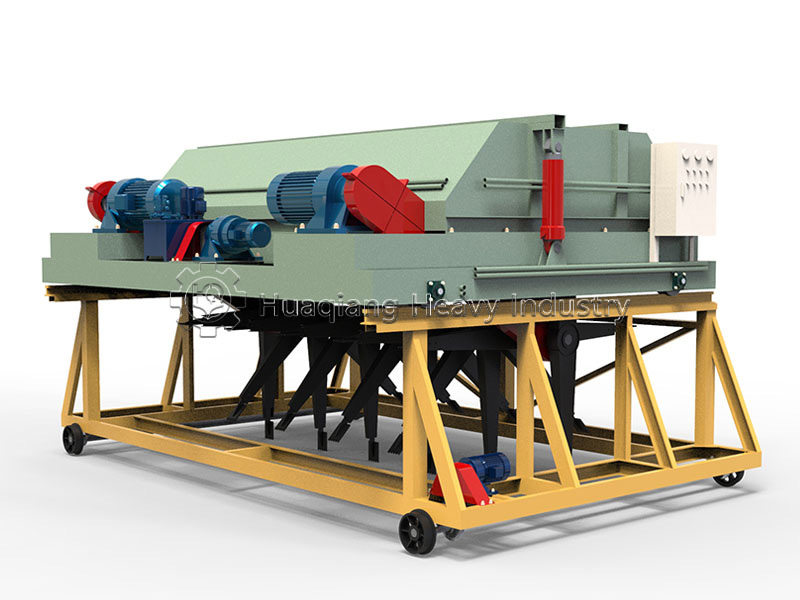

It accelerates the decomposition of organic materials through turning, mixing, and oxygen supply, facilitating the production of organic fertilizer or bioenergy raw materials. The equipment consists of a walking mechanism, a turning and mixing mechanism, a hydraulic system, an oxygen supply system, a control system, and a safety protection system. The walking mechanism drives the equipment to move along the fermentation trough, the turning and mixing mechanism penetrates the material pile for mixing, the hydraulic system provides power, and the control system realizes automated operation, ensuring safety and efficiency.

Its advantages are significant: strong power, capable of handling high-density and high-viscosity materials; precise adjustment of turning depth, speed, and oxygen supply to improve fermentation quality; stable operation, high degree of automation, reducing labor costs; wide adaptability, capable of handling various organic wastes; and it is environmentally friendly and energy-saving, promoting the resource utilization of organic waste.

In short, the hydraulic compost turning machine, as a core organic fertilizer production equipment, provides raw material processing assurance for organic fertilizer production lines with its wide range of material adaptability, and is a key equipment for promoting the resource utilization of organic waste and contributing to the development of the organic fertilizer industry.