For individual farms and small planting cooperatives, there’s no need to invest in large-scale, complete sets of organic fertilizer production equipment. By choosing the right core equipment, such as simple compost turning machines and flat die pelleting machines, you can build an efficient and practical organic fertilizer production line and easily achieve the resource utilization of organic waste. This “streamlined” equipment combination lowers the entry barrier while meeting the quality requirements of small-scale production.

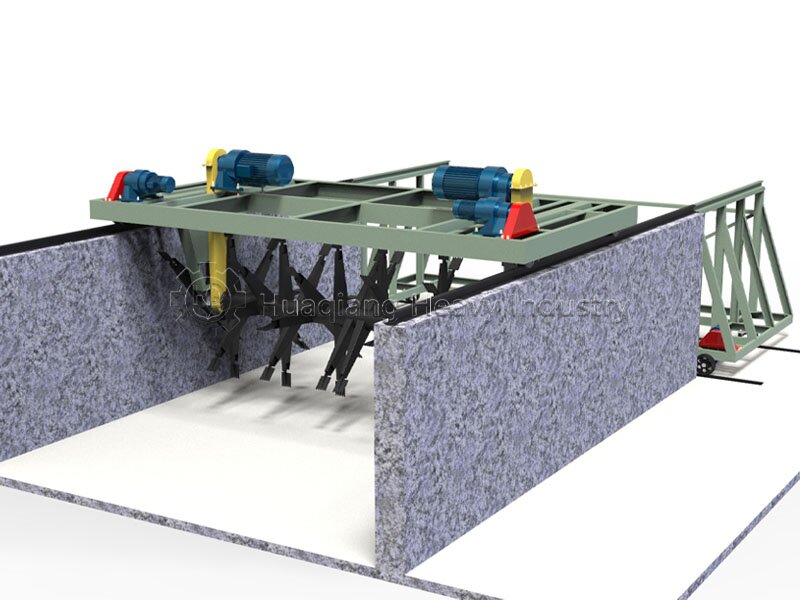

The simple compost turning machine is the “cost-effective choice” for the fermentation stage of small and medium-scale production lines. It has a simple structure and is easy to operate, requiring no complex installation or debugging, and can be operated by a single person. For common raw materials such as crop straw and livestock manure, its turning mechanism effectively provides oxygen to the materials, meeting the basic requirements of aerobic fermentation. Although the processing capacity per batch is limited, its flexibility and efficiency make it very suitable for the batch fermentation model in small-scale facilities.

After fermentation and maturation, the material can be processed into granules using a flat die pelleting machine. As a key organic fertilizer production equipment suitable for small and medium-scale production lines, the flat die pelleting machine features a small size, low energy consumption, and easy maintenance. It has a wide range of adaptability to the moisture content of raw materials, and can produce stable output even if the moisture content of the material processed by the simple compos turning machine fluctuates slightly, effectively solving the problem of unstable raw material characteristics in small-scale production.