Poor pellet formation is a common problem with flat die granulators. Improper material moisture is the primary cause. Excessively high moisture content can cause the material to stick together, making it difficult to form; while excessively low moisture content can lead to a lack of cohesiveness and loose pellets. Die wear can also cause forming problems, resulting in irregular die holes and poor pellet quality. Insufficient roller pressure can also prevent the material from being fully extruded. Solutions include strictly controlling material moisture content to maintain it within the appropriate range; regularly inspecting and replacing severely worn dies; and adjusting roller pressure to ensure uniform and adequate pressure.

Abnormal equipment noise is often caused by multiple factors. Bearing damage is a common cause, producing abnormal noise during operation. Loose components, such as loose screws and connectors, are also important, as they can generate vibration and noise during operation. Gear wear can also increase noise, as worn gears mesh poorly. If these problems occur, promptly inspect the bearings, tighten loose components, and replace damaged gears as necessary to reduce noise and ensure proper operation.

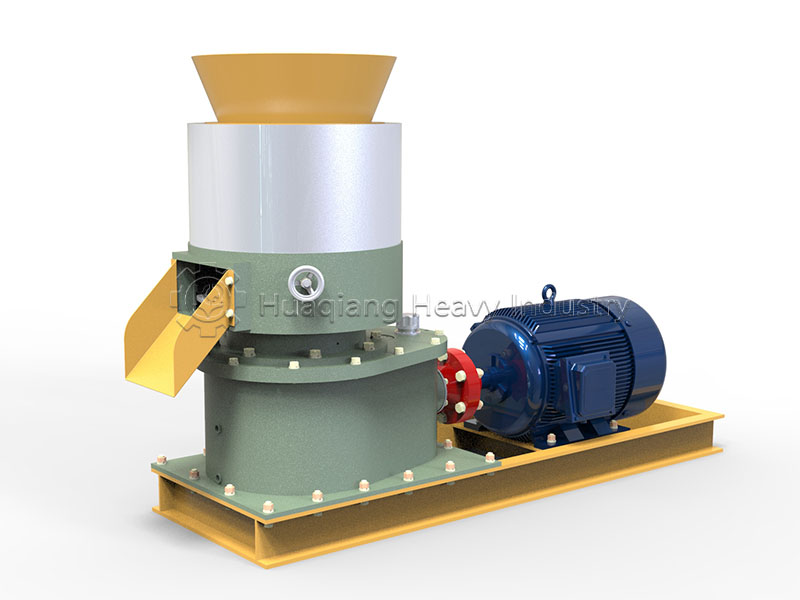

Routine maintenance is crucial to minimizing flat die granulator failures. Regularly check the wear of equipment components, such as rollers, dies, and bearings, and replace wearing parts promptly. Keep the flat die granulator clean to prevent residual material from corroding the equipment. Lubricate the equipment regularly to reduce friction between components. These routine maintenance measures can effectively reduce the incidence of equipment failures, extend equipment life, and improve production efficiency.