In modern organic fertilizer production lines, the double screws compost turning machine, as a crucial piece of equipment, provides a professional and reliable solution for the aerobic fermentation stage. This equipment complements the common large wheel compost turning machine, together forming a complete material handling system.

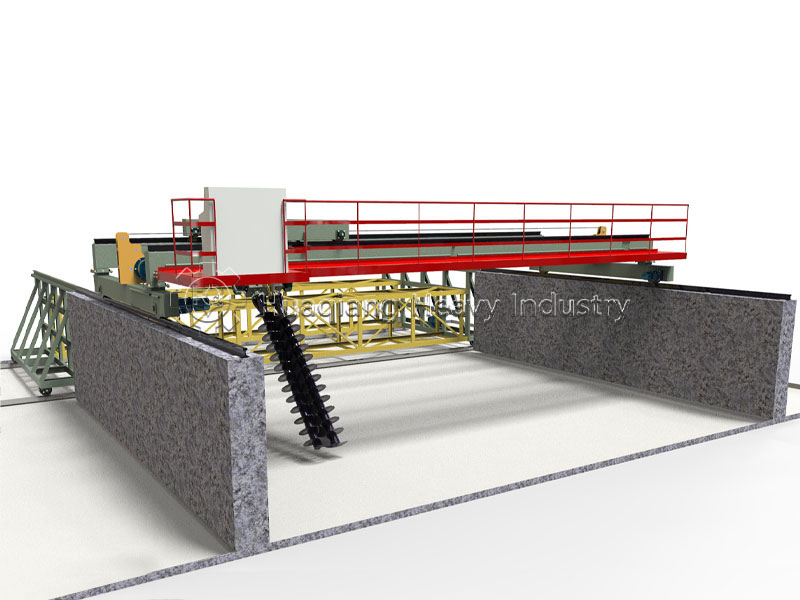

As a key piece of equipment in organic fertilizer production lines, the double screws compost turning machine’s design is characterized by its unique double-helix structure. Two parallel spiral shafts work in tandem under power drive, enabling deep turning of the material within the fermentation tank. This design not only ensures thorough turning but also significantly improves processing efficiency, making it an important member of the modern organic fertilizer production equipment system.

In practical applications, the double screws compost turning machine works perfectly with trough fermentation processes. Its processing depth typically reaches over two meters, effectively breaking up the compacted layer formed during fermentation and ensuring uniform oxygen distribution in the material. Compared to large wheel compost turning machines, this equipment is more suitable for operation within fixed fermentation tanks, demonstrating unique environmental adaptability.

In the configuration of organic fertilizer production lines, the double screws compost turning machine and the large wheel compost turning machine each have their own advantages. Large wheel compost turning machines are typically suitable for windrow fermentation in open areas, while double screws compost turning machines excel in trough fermentation processes. This combination of equipment provides organic fertilizer producers with more flexible and diverse process options, meeting the needs of different site conditions and production scales.

With the continuous development of the organic fertilizer industry, double-helix compost turning technology is also constantly innovating. These technological advancements not only improve equipment performance but also drive the entire organic fertilizer production equipment system towards greater efficiency and intelligence.