In the industrial development of organic fertilizers, the granulation process is a core link in the organic fertilizer production line, and its level directly determines the quality and capacity of the finished fertilizer. As a key piece of organic fertilizer production equipment, the new type organic fertilizer granulator, with its intelligent and multi-functional advantages, makes fertilizer granulation more efficient and produces higher-quality finished products.

The core of the new organic fertilizer granulation process consists of three main steps. The first step is raw material preparation, where fermented and decomposed livestock manure, straw, and other organic raw materials are mixed with nitrogen, phosphorus, and potassium and other nutritional additives in appropriate proportions, while adjusting the moisture content to a suitable range to ensure good binding properties of the raw materials. This step requires the precise proportioning function of the organic fertilizer production equipment, strictly controlling parameter accuracy, which directly affects the nutritional balance of the finished fertilizer and is a prerequisite for the smooth progress of subsequent granulation.

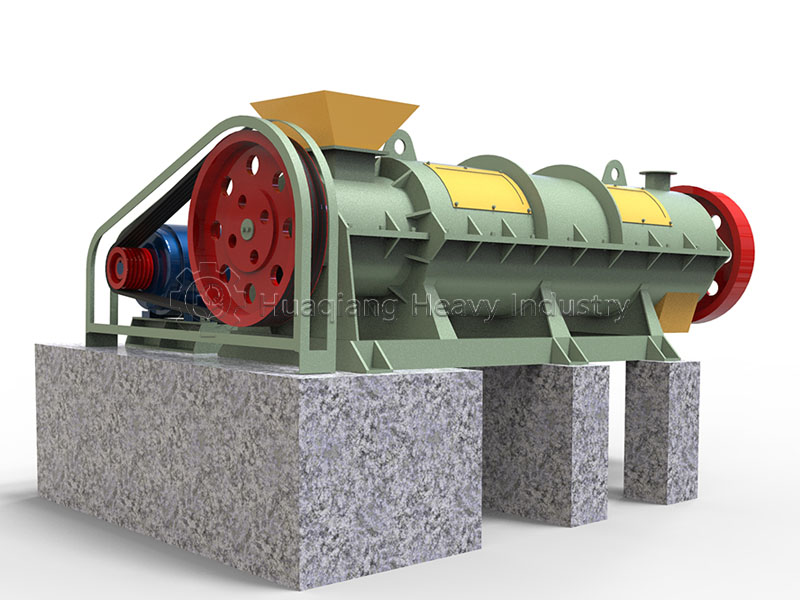

The second step is the core granulation process. The new granulator uses extrusion granulation, which is suitable for materials with higher hardness. High-pressure extrusion is used to shape the raw materials; the new equipment also features intelligent temperature control and variable frequency speed regulation functions, allowing for flexible adjustment of parameters according to different raw material characteristics, significantly improving the granulation success rate.

The third step is the post-processing procedure. The formed granules need to undergo drying, cooling, and screening. The drying process removes excess moisture from the granules to prevent mildew during storage; cooling increases the hardness of the granules, facilitating transportation; and screening separates unqualified granules for reprocessing, ensuring uniform particle size of the finished product.

The upgrade of the new organic fertilizer granulation process, coupled with the coordinated operation of a complete set of organic fertilizer production equipment, not only improves the overall efficiency of the organic fertilizer production line but also enhances product market competitiveness, driving the organic fertilizer industry towards high-quality development.