In modern agricultural production, organic fertilizers are increasingly valued for their positive effects on soil and crops. Organic fertilizers can not only provide nutrients for plant growth, but also improve soil structure, promote soil microbial activity, and improve soil fertility and water retention capacity. This paper will introduce several common organic fertilizers, and discuss the related fertilizer granulator equipment.

1. Compost (Compost)

Compost is a kind of organic fertilizer formed by decomposition and fermentation of organic matter such as plant residues and kitchen waste under the action of microorganisms. It contains rich organic matter and a variety of trace elements, which can improve the biological activity and fertility of soil.

2. Green Manure

Green manure is the planting of specific plants, such as legumes, which are turned into the soil during their growth, and the decomposition of plant residues is used to increase soil organic matter and nutrients. Green manure can also improve soil structure and increase soil water retention and permeability.

3. Animal Manure

Animal manure is another common organic fertilizer, such as cow manure, chicken manure, etc. They are rich in nitrogen, phosphorus, potassium and other major nutrients needed for plant growth, as well as providing organic matter needed by soil microorganisms.

4. Biogas Slurry

Biogas residue, a byproduct of biogas fermentation, is rich in organic matter and microorganisms, which can improve soil fertility and soil structure.

In the production process of organic fertilizer, fertilizer granulator equipment plays a crucial role. The following are several types of fertilizer granulator equipment related to organic fertilizer production:

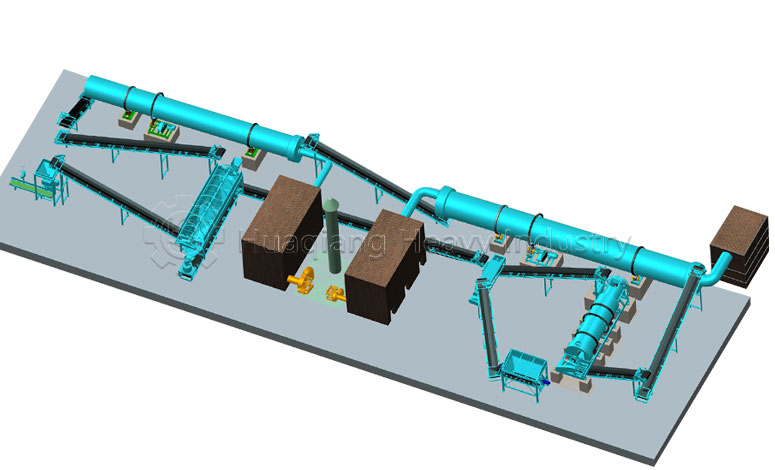

- Organic Fertilizer Production Line: This is a production line specially used for the production of organic fertilizer, including multiple links, such as raw material treatment, fermentation, drying, granulation, etc., to ensure the quality and effect of organic fertilizer.

- Rotary Drum Granulator: This type of granulator makes organic fertilizer raw materials into pellets through the rotation of the drum and the friction of the material, which is convenient for storage and application.

- Disc Granulator: Disc Granulator makes organic fertilizer raw materials into uniform particles by rotating the disk and centrifugal force of the material, improving the application effect of fertilizer.

- Fertilizer Granules Compaction Machine: This type of granulator squeezes materials by two rollers rotating in opposite directions to form particles. It is suitable for the production of high-density, high-hardness organic fertilizer particles, which helps to improve the storage and transportation efficiency of fertilizers.

Through these advanced fertilizer granulator equipment, the production efficiency and quality of organic fertilizer can be effectively improved to meet the needs of modern agriculture for efficient and environmentally friendly fertilizers. At the same time, the application of these devices also helps to promote the popularization and application of organic fertilizers and promote the sustainable development of agriculture.