With the large-scale development of the organic fertilizer industry, production lines are placing increasingly stringent demands on equipment adaptability. With its exceptional integration capabilities, large wheel compost turners have become core equipment for large-scale organic fertilizer production lines.

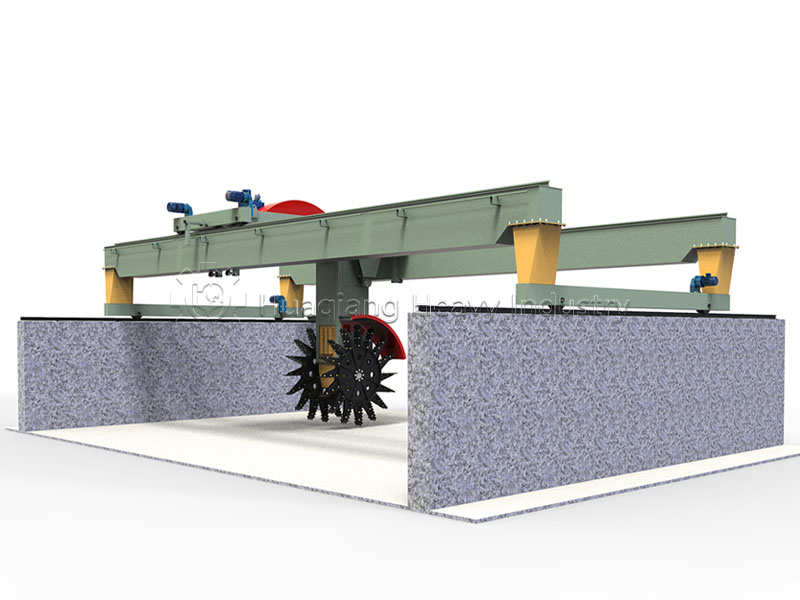

Within the production line process, they seamlessly connect pre-treatment and processing. During pre-treatment, raw materials such as livestock and poultry manure processed by a solid-liquid separator and pulverized straw from a pulverizer are piled into windrows 5-8 meters wide and 1.5-2 meters high. The large wheel compost turner slowly moves along the windrows, turning and fermenting the material. The fermented material is then conveyed by conveyor to equipment such as granulators, screens, and dryers, forming a complete production chain from pre-treatment to fermentation, enabling continuous production.

For large-scale production lines with an annual output of over 100,000 tons, the equipment rotates through multiple windrows: one receiving fresh raw material, one performing high-temperature fermentation, and one completing cool-down composting. This fixed cycle allows for a daily processing capacity of 800-1,500 tons, meeting the needs of large-scale production.

In addition, its electronic control system flexibly adjusts the turning and travel speeds, adjusting the fermentation progress based on the raw material supply and pelletizing capacity, ensuring a stable production line. Furthermore, compared to tank fermentation, it improves site utilization by over 30%, saving valuable land resources for large-scale production lines.